Explosion Proof Three-phase Induction Motor for Axial Ventilator, YBT-H Series

YBT-H Series Explosion-Proof Three Phase Marine Induction Motor For Vetilator

- Introduction

- Operating Conditions

- Main Technical Data

The explosion-proof three-phase induction motors are designed and manufactured according to National Standard GB3836.1 for "electric apparatuses in explosive gas environments–part 1: general requirement" and GB3836.2 "Electric apparatuses in explosive gas environments–part 2: flameproof enclosure D." The induction motor features high efficiency, large rotation, low noise and safety devices and can be used with flameproof ventilators on ships as well as in environments with hazardous gases. The protection type of the marine motor is Exd ⅡBT4, with a temperature class from T1 to T4.

Details: The rated voltage is 380V or 440V and the rated frequency is 50 Hz or 60 Hz. The housing protection grade is IP56, avec insulation F. The duty type is S1. If the power is less than 3 kW, the connection is Y, otherwise, the connection is △.

Operation Condition

Ambient temperature:-20℃~45℃

Altitude: 0m

Longitudinal ramp: 10°

Ramp: 15°

Relative Humidity: ≤95%

Shock, vibration, dew, salt mist, oil mist, fungus: exists

Inclination and swing: ±22.5°

| Type | Power (kW) | Current (A) | Rotate speed (r/min) | Type | Power (kW) | Current (A) | Rotate speed (r/min) | ||||

| 380V 50Hz | 440V 60Hz | 380V 50Hz | 440V 60Hz | 380V 50Hz | 440V 60Hz | 380V 50Hz | 440V 60Hz | ||||

| 0.75 | 1.8 | 1.6 | 2820 | 3460 | 22.0 | 42.2 | 36.9 | 1470 | 1770 | ||

| 1.1 | 2.6 | 2.2 | 2820 | 3460 | 30.0 | 57.3 | 49.8 | 1476 | 1779 | ||

| 1.5 | 3.5 | 3.1 | 2840 | 3470 | 45.0 | 84.0 | 73.4 | 1480 | 1783 | ||

| 2.2 | 4.9 | 4.3 | 2840 | 3470 | 55.0 | 103.8 | 88.6 | 1480 | 1780 | ||

| 3.0 | 6.2 | 5.4 | 2880 | 3490 | 0.75 | 2.2 | 2.0 | 910 | 1130 | ||

| 4.0 | 8.2 | 7.1 | 2890 | 3500 | 1.1 | 3.2 | 2.9 | 910 | 1130 | ||

| 5.5 | 11.0 | 9.6 | 2900 | 3520 | 1.5 | 4.0 | 3.5 | 940 | 1150 | ||

| 7.5 | 14.6 | 12.9 | 2900 | 3520 | 2.2 | 5.6 | 4.9 | 940 | 1150 | ||

| 11.0 | 21.6 | 18.7 | 2930 | 3540 | 3.0 | 7.2 | 6.4 | 960 | 1170 | ||

| 15.0 | 28.9 | 25.1 | 2930 | 3540 | 4.0 | 9.5 | 8.2 | 960 | 1170 | ||

| 18.5 | 35.7 | 30.3 | 2930 | 3540 | 5.5 | 12.5 | 10.7 | 960 | 1170 | ||

| 22.0 | 42.2 | 36.9 | 2940 | 3550 | 7.5 | 17.1 | 14.8 | 970 | 1170 | ||

| 30.0 | 57.9 | 50.3 | 2935 | 3560 | 11.0 | 25.0 | 21.7 | 970 | 1170 | ||

| 37.0 | 69.4 | 60.3 | 2960 | 3565 | 15.0 | 33.0 | 29.3 | 970 | 1180 | ||

| 45.0 | 85.9 | 76.3 | 2969 | 3572 | 18.5 | 37.6 | 32.7 | 980 | 1183 | ||

| 55.0 | 103.2 | 91.7 | 2970 | 3570 | 22.0 | 44.7 | 38.9 | 980 | 1182 | ||

| 0.55 | 1.5 | 1.4 | 1390 | 1710 | 30.0 | 61.1 | 53.1 | 985 | 1187 | ||

| 0.75 | 2.1 | 1.8 | 1390 | 1710 | 37.0 | 71.0 | 61.3 | 980 | 1180 | ||

| 1.1 | 2.7 | 2.4 | 1400 | 1710 | 2.2 | 5.8 | 5.2 | 710 | 860 | ||

| 1.5 | 3.6 | 3.2 | 1400 | 1710 | 3.0 | 7.6 | 6.8 | 710 | 860 | ||

| 2.2 | 5.0 | 4.5 | 1420 | 1730 | 4.0 | 10.5 | 9.1 | 720 | 870 | ||

| 3.0 | 6.8 | 5.9 | 1420 | 1730 | 5.5 | 13.4 | 11.5 | 720 | 870 | ||

| 4.0 | 8.8 | 7.7 | 1440 | 1750 | 7.5 | 17.7 | 15.5 | 720 | 870 | ||

| 5.5 | 11.7 | 10.0 | 1440 | 1750 | 11.0 | 25.6 | 22.2 | 730 | 880 | ||

| 7.5 | 15.4 | 13.2 | 1440 | 1750 | 15.0 | 33.3 | 29.2 | 729 | 882 | ||

| 11.0 | 22.6 | 19.5 | 1460 | 1760 | 22.0 | 47.4 | 41.7 | 734 | 886 | ||

| 15.0 | 30.5 | 26.3 | 1460 | 1760 | 30.0 | 64.7 | 57.1 | 730 | 890 | ||

| 18.5 | 35.9 | 30.8 | 1470 | 1770 | |

||||||

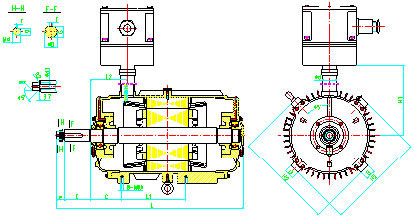

| Frame size | Mounting and overall dimensions | |||||||||||||||||

| B | C | D | E | F | G | H1* | H2 | e | L | L1 | L2 | d | d1 | g | f | M × t | M Length h | |

| 801 | 36 | 58 ± 2 | 19 | 40 | 6 | 15.5 | 176 | 175 | 28 | 330 | 100 | 90 | 60 | 13.8 | 12 | 5 | M16 × 1.5 | M8 Length 14 |

| 802 | 36 | 58 ± 2 | 201 | 175 | 28 | 330 | 100 | 90 | 60 | 13.8 | 12 | 5 | M16 × 1.5 | M8 Length 14 | ||||

| 90S | 36 | 62 ± 2 | 24 | 50 | 8 | 20 | 280 | 190 | 28 | 340 | 100 | 90 | 60 | 15.8 | 14 | 5 | M18 × 1.5 | M8 Length 14 |

| 90L | 36 | 62 ± 2 | 226 | 190 | 28 | 375 | 125 | 90 | 60 | 15.8 | 14 | 5 | M18 × 1.5 | M8 Length 14 | ||||

| 100L 1 | 40 | 68 ± 2 | 28 | 60 | 24 | 280/330/380 | 220 | 28 | 410 | 140 | 93 | 60 | 17.8 | 16 | 5 | M20 × 1.5 | M10 Length 17 | |

| 100L 2 | 40 | 68 ± 2 | 280/380 | 220 | 28 | 410 | 140 | 93 | 60 | 17.8 | 16 | 5 | M20 × 1.5 | M10 Length 17 | ||||

| 112M | 40 | 76 ± 2 | 280/380/410 | 245 | 28 | 430 | 140 | 102 | 60 | 17.8 | 16 | 5 | M20 × 1.5 | M10 Length 17 | ||||

| 132S1 | 40 | 89 ± 2 | 38 | 80 | 10 | 33 | 280/435 | 285 | 32 | 450 | 140 | 120 | 60 | 21.8 | 20 | 5 | M24 × 1.5 | M10 Length 17 |

| 132M | 40 | 89 ± 2 | 410/435/485 | 285 | 32 | 495 | 178 | 120 | 60 | 21.8 | 20 | 5 | M24 × 1.5 | M10 Length 17 | ||||

| 160M | 46 | 114 ± 3 | 42 | 110 | 12 | 37 | 435/485/535 | 345 | 32 | 596 | 210 | 162 | 60 | 24.8 | 23 | 5 | M27 × 1.5 | M14 Length 17 |

| 160L | 46 | 114 ± 3 | 485/535/585 | 345 | 32 | 646 | 254 | 162 | 60 | 24.8 | 23 | 5 | M27 × 1.5 | M14 Length 17 | ||||

| 180M | 54 | 126 ± 3 | 48 | 14 | 42.5 | 485/585 | 380 | 32 | 702 | 241 | 174 | 60 | 27.8 | 26 | 5 | M30 × 1.5 | M14 Length 22 | |

| 180L | 54 | 126 ± 3 | 535/585/642 | 380 | 32 | 740 | 279 | 174 | 60 | 27.8 | 26 | 5 | M30 × 1.5 | M14 Length 22 | ||||

| 200L 1 | 60 | 133 ± 3 | 55 | 16 | 49 | 585/642 | 430 | 32 | 740 | 305 | 186 | 60 | 30.8 | 29 | 6 | M33 × 1.5 | M16 Length 26 | |

| 200L 2 | 60 | 133 ± 3 | 742 | 430 | 32 | 740 | 305 | 186 | 60 | 30.8 | 29 | 6 | M33 × 1.5 | M16 Length 26 | ||||

| 225M | 70 | 149 ± 4 | 60 | 140 | 18 | 53 | 642/735/742 | 480 | 32 | 870 | 311 | 196 | 76 | 33.8 | 32 | 6 | M36 × 1.5 | M18 Length 30 |

| 250M | 70 | 168 ± 4 | 65 | 140 | 18 | 58 | 740 | 526 | 40 | 1000 | 340 | 196 | 76 | 38 | 38 | 8 | M42 × 1.5 | M16 Length 24 |

| Note: H1 can be customized. |

||||||||||||||||||

English

English Русский

Русский العربية

العربية