Variable Frequency Adjustable Speed Marine Use Three Phase Induction Motor

- Introduction

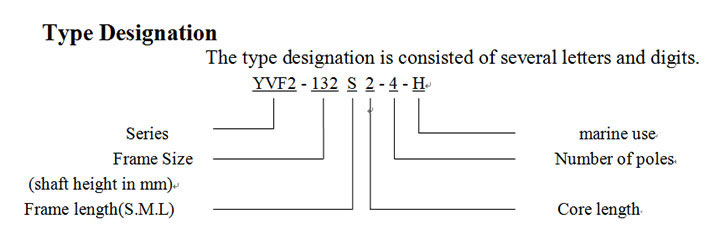

- Type Designation

- Operating Conditions

- Main Technical Data

- Ordering Information

The YVF2-H series of variable frequency adjustable speed three-phase induction motor is an energy-efficient AC adjustable speed motor. Equipped with a frequency converter, the induction motor features low noise and vibration, a high starting torque, small starting current, and reliable operation. Flat and step less speed regulation can be done in 3(5)~100Hz or more and an independent forced cooling fan makes the motor long lasting. The motor drives various machines on ships such as pumps, blowers, separators, hydraulic engines and other auxiliary equipment.

This series is designed according to IEC60034-1《Rotating Electrical Machines—Rating And Performance》and "Rules for the Construction of Sea-Going Steel Ships." Motors also comply with the following specifications.

IEC60034 Rotating electrical machines

IEC60068 Environmental testing

IEC60072 Dimensions and power ratings for rotating electrical machines

IEC60092 Marine electric accessories

The motors also meet international standards for the following Ship Classification Societies:

LR Lloyd’s Register of Shipping

GL Germanischer Lloyd

NK Nippon Kaiji Kyokai

BV Bureau Veritas

KR Korea Register of shipping

RINA Registro Italiano Navale

ABS American Bureau of Shipping

The type and size of bearings used in these motors are given in table 1. Table 1

| Frame Size | No. of Poles | Bearings | ||

| Driving End | Non-Driving End | |||

| B3, B5, B35 | V1 | |||

| 80 | 4, 6 | 6204-2R S /C3 | 6204-2RS/C3 | |

| 90 | 4, 6 | 6205-2RS/C3 | 6205-2RS/C3 | |

| 100 | 4, 6 | 6206-2RZ/C3 | 6206-2RZ/C3 | |

| 112 | 4, 6, 8 | 6206-2RZ/C3 | 6206-2RZ/C3 | |

| 132 | 4, 6, 8 | 6208-2RZ/C3 | 6208-2RZ/C3 | |

| 160 | 4, 6, 8 | 6309-2RZ/C3 | 6309-2RZ / C3 | |

| 180 | 4, 6, 8 | 6311 / C3 | 6311 / C3 | |

| 200 | 4, 6, 8 | 6312 / C3 | 6312 / C3 | |

| 225 | 4, 6, 8 | 6313 / C3 | 631 2 / C3 | |

| 250 | 4, 6, 8 | 6314 / C3 | 631 3 / C3 | |

| 280 | 4, 6, 8 | 631 7/ C3 | 631 4 / C3 | |

| 315 | 4, 6, 8 | 631 9/ Z2 | 7319ACJ | 6319/Z2 |

| 355 | 4, 6, 8 | 6322 / Z2 | 7322ACJ | 6322/Z2 |

Operating Conditions

Ambient temperature: 0℃~45℃

Altitude: 0m

Relative humidity: ≤95%

Frozen dew: Exist

Salt mist: Exist

Oil mist: Exist

Fungus: Exist

Shock: Exist

Vibration: Exist

Inclination and Swing: ±22.5°

Voltage and Frequency

Rated voltage: 380V

Rated frequency: 50Hz

Range of Frequency

The frame of motors from 80 to 225 with a permanent torque range of 5~50Hz have a power range frequency of 50~100Hz. The frame of motors from 250 to 355 with a permanent torque range of 3~50Hz have a power range frequency of 50~100Hz.

Duty Type

Continuous(S1)

Insulation, Temperature Rise

Insulation F

Temperature rise of winding (resistance method): 100K

Allowable working temperature of bearing: 90℃

Driving Method

Pulley, spur of flexible coupling can be used for driving.

Noise

When using the frequency converter as the power supply, the noise limits (A sound power level) of the motors measured at the no-load conditions are given in Table 2.

Vibration

When using the frequency converter as the power supply, the effective values of vibration intensity bound measured at no-load conditions do not exceed those given in table 3.

Mounting arrangements

Mounting arrangements are available for various frame sizes shown in Table 4. We can also provide customized mounting arrangements.

B3 Horizontal, foot-mounted

B5 Horizontal flange-mounted

B35 Horizontal, foot and flange mounted

V1 Vertical, flange mount

| Power kW | Synchronous Speed r/min | ||

| 1500 | 1000 | 750 | |

| Sound Power Level dB(A) | |||

| 0.55 | 79 | 79 | 79 |

| 0.75 | |||

| 1.1 | |||

| 1.5 | 83 | 83 | 83 |

| 2.2 | |||

| 3 | 87 | 87 | 87 |

| 4 | |||

| 5.5 | 91 | 91 | 91 |

| 7.5 | |||

| 11 | 93 | 93 | 93 |

| 15 | |||

| 18.5 | |||

| 22 | 98 | 98 | 98 |

| 30 | 101 | 101 | 101 |

| 37 | |||

| 45 | 103 | 103 | 103 |

| 55 | |||

| 75 | 105 | 105 | 105 |

| 90 | |||

| 110 | 107 | 107 | 107 |

| 132 | |||

| 160 | 109 | 109 | 109 |

| 200 | |||

| 250 | 111 | - | - |

| 315 | |||

| 355 | 113 | 113 | 113 |

| Frame size | ≤ 132 | > 132 ~ 225 | > 225 ~ 500 |

| Vibration intensity bound mm/s | 1.8 | 2.8 | 3.5 |

| Frame size | Mounting Arrangements ( IM ) |

| 80 ~ 280 | B3, B5, B35, V1 |

| 315 ~ 355 | B3, B35, V1 |

Impregnation and Surface Treatment

The surfaces of the motors’ winding and metal spares are impregnated and well treated to be waterproof and resistant to fungus, mold and sea spray in accordance with specifications for machines in humid environments.

Technical Data

Technical data for motors are given in tables 5-7. Upon request, we can produce 2-pole motors.

Note: All data is for reference only and may change depending upon specifications of your order. Contact us with any questions.

| Frame size | Rated power(kW) | Rated Current (A) | Rated torque (N· m ) | Max torque/ Rated torque | Permanent torque range of frequency (Hz) | Permanent power range of frequency (Hz) |

| YVF2-80M1-4-H | 0.55 | 1.5 | 3.5 | 2.3 | 5 ~ 50 | 50 ~ 100 |

| YVF2-80M2-4-H | 0.75 | 2.1 | 4.7 | |||

| YVF2-90S-4-H | 1.1 | 2.7 | 7.0 | |||

| YVF2-90L-4-H | 1.5 | 3.6 | 9.5 | |||

| YVF2-100L 1 -4-H | 2.2 | 5.0 | 14.0 | |||

| YVF2-100L 2 -4-H | 3 | 6.8 | 19.0 | |||

| YVF2-112M-4-H | 4 | 8.9 | 25.4 | |||

| YVF2-132S-4-H | 5.5 | 11.7 | 35.0 | |||

| YVF2-132M-4-H | 7.5 | 15.4 | 47.7 | |||

| YVF2-160M-4-H | 11 | 22.6 | 70.0 | |||

| YVF2-160L-4-H | 15 | 30.5 | 95.5 | |||

| YVF2-180M-4-H | 18.5 | 35.9 | 117.1 | |||

| YVF2-180L-4-H | 22 | 42.2 | 140.9 | |||

| YVF2-200L-4-H | 30 | 57.3 | 190.9 | |||

| YVF2-225S-4-H | 37 | 70.2 | 235.5 | |||

| YVF2-225M-4-H | 45 | 84.0 | 286.4 | |||

| YVF2-250M-4-H | 55 | 104 | 350.1 | 3 ~ 50 | ||

| YVF2-280S-4-H | 75 | 139 | 477.7 | |||

| YVF2-280M-4-H | 90 | 164 | 572.9 | |||

| YVF2-315S-4-H | 110 | 201 | 700.2 | 2.2 | ||

| YVF2-315M-4-H | 132 | 240 | 840.3 | |||

| YVF2-315L 1 -4-H | 160 | 289 | 1018 | |||

| YVF2-315L 2 -4-H | 200 | 361 | 1273 | |||

| YVF2-355M-4-H | 250 | 464 | 1592 | |||

| YVF2-355L-4-H | 315 | 582 | 2005 |

| Frame size | R ated power (kW) | Rated Current (A) | Rated torque (N· m ) | Max torque/ Rated torque | Permanent torque range of frequency (Hz) | Permanent power range of frequency (Hz) |

| YVF2-90S-6-H | 0.75 | 2.2 | 7.2 | 2.1 | 5 ~ 50 | 50 ~ 100 |

| YVF2-90L-6-H | 1.1 | 3.2 | 10.5 | |||

| YVF2-100L-6-H | 1.5 | 4.0 | 14.3 | |||

| YVF2-112M-6-H | 2.2 | 5.8 | 21 .0 | |||

| YVF2-132S-6-H | 3 | 7.2 | 28.7 | |||

| YVF2-132M 1 -6-H | 4 | 9.5 | 38.2 | |||

| YVF2-132M 2 -6-H | 5.5 | 12.5 | 52.5 | |||

| YVF2-160M-6-H | 7.5 | 17.1 | 71.6 | |||

| YVF2-160L-6-H | 11 | 25.0 | 105 .1 | |||

| YVF2-180L-6-H | 15 | 33.0 | 143 .2 | |||

| YVF2-200L 1 -6-H | 18.5 | 37.6 | 17 6. 7 | |||

| YVF2-200L 2 -6-H | 22 | 44.7 | 210 .1 | |||

| YVF2-225M-6-H | 30 | 61.1 | 286.5 | |||

| YVF2-250M-6-H | 37 | 71.0 | 353.4 | 3 ~ 50 | ||

| YVF2-280S-6-H | 45 | 86.4 | 429.8 | 2.0 | ||

| YVF2-280M-6-H | 55 | 103 | 525.3 | |||

| YVF2-315S-6-H | 75 | 141 | 716.3 | 2.0 | 3 ~ 50 | 50 ~ 100 |

| YVF2-315M-6-H | 90 | 169 | 859.5 | |||

| YVF2-315L 1 -6-H | 110 | 205 | 105 1 | |||

| YVF2-315L 2 -6-H | 132 | 246 | 126 1 | |||

| YVF2-355M 1 -6-H | 160 | 302 | 1528 | |||

| YVF2-355M 2 -6-H | 200 | 377 | 1910 | |||

| YVF2-355L-6-H | 250 | 469 | 238 8 |

| Frame size | R ated power (kW) | Rated Current (A) | Rated torque (N· m ) | Max torque/ Rated torque | Permanent torque range of frequency (Hz) | Permanent power range of frequency (Hz) |

| YVF2-132S-8-H | 2.2 | 5.8 | 2 8. 0 | 2.0 | 5 ~ 50 | 50 ~ 100 |

| YVF2-132M-8-H | 3 | 7.6 | 38.2 | |||

| YVF2-160M 1 -8-H | 4 | 10.5 | 50.9 | |||

| YVF2-160M 2 -8-H | 5.5 | 13.4 | 70.0 | |||

| YVF2-160L-8-H | 7.5 | 17.7 | 95. 5 | |||

| YVF2-180L-8-H | 11 | 25.6 | 1 40. 1 | |||

| YVF2-200L-8-H | 15 | 33.3 | 191.0 | |||

| YVF2-225S-8-H | 18.5 | 40.3 | 235.6 | |||

| YVF2-225M-8-H | 22 | 47.4 | 278.1 | |||

| YVF2-250M-8-H | 30 | 64.7 | 382.0 | 3 ~ 50 | ||

| YVF2-280S-8-H | 37 | 79.8 | 471.1 | |||

| YVF2-280M-8-H | 45 | 94.8 | 573.0 | |||

| YVF2-315S-8-H | 55 | 114 | 700.3 | |||

| YVF2-315M-8-H | 75 | 152 | 955 .0 | |||

| YVF2-315L 1 -8-H | 90 | 179 | 114 6 | |||

| YVF2-315L 2 -8-H | 110 | 218 | 1 400 | |||

| YVF2-355M 1 -8-H | 132 | 265 | 16 81 | |||

| YVF2-355M 2 -8-H | 160 | 320 | 203 7 | |||

| YVF2-355L-8-H | 200 | 399 | 254 7 |

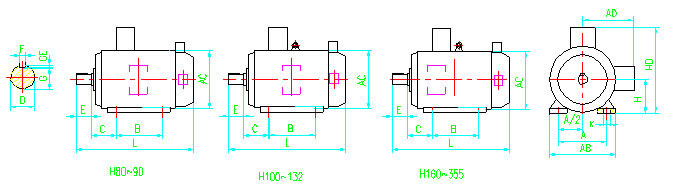

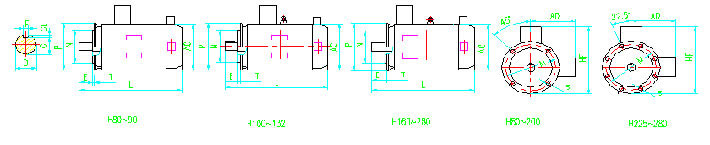

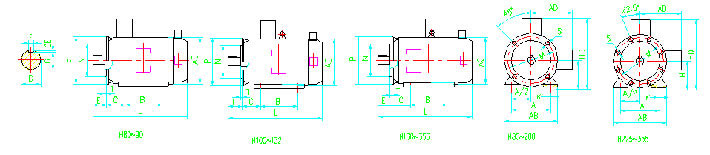

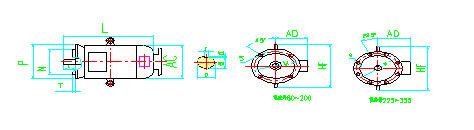

Mounting and Overall Dimensions

Various mounting types and overall dimensions are shown respectively in Table.8 to 11.

| Frame Size | Mounting Dimensions | Overall Dimensions | ||||||||||||

| A | B | C | D | E | F | G a | H | K b | AB | AC | AD | HD | L | |

| Basic Dimension | Basic Dimension | Basic Dimension | Basic Dimension | Basic Dimension | Basic Dimension | Basic Dimension | Basic Dimension | Basic Dimension | ||||||

| 80M | 125 | 100 | 50 | 19 | 40 | 6 | 15.5 | 80 | 10 | 165 | 165 | 145 | 220 | 3 7 0 |

| 90S | 140 | 56 | 24 | 50 | 8 | 20 | 90 | 180 | 195 | 1 55 | 250 | 400 | ||

| 90L | 125 | 430 | ||||||||||||

| 100L | 160 | 140 | 63 | 28 | 60 | 24 | 100 | 12 | 205 | 215 | 18 0 | 270 | 465 | |

| 112M | 190 | 70 | 10 | 112 | 230 | 240 | 190 | 300 | 4 9 0 | |||||

| 132S | 216 | 89 | 38 | 80 | 33 | 132 | 270 | 275 | 21 0 | 345 | 5 30 | |||

| 132M | 178 | 57 5 | ||||||||||||

| 160M | 254 | 210 | 108 | 42 | 110 | 12 | 37 | 160 | 15 | 320 | 330 | 255 | 420 | 6 60 |

| 160L | 254 | 715 | ||||||||||||

| 180M | 279 | 241 | 121 | 48 | 14 | 42.5 | 180 | 355 | 380 | 2 8 0 | 45 5 | 810 | ||

| 180L | 279 | 850 | ||||||||||||

| 200L | 318 | 305 | 133 | 55 | 16 | 49 | 200 | 19 | 395 | 420 | 305 | 505 | 890 | |

| 225S | 356 | 286 | 149 | 60 | 140 | 18 | 53 | 225 | 435 | 470 | 3 35 | 560 | 930 | |

| 225M | 311 | 18 | 970 | |||||||||||

| 250M | 406 | 349 | 168 | 65 | 58 | 250 | 24 | 490 | 5 1 0 | 370 | 615 | 1050 | ||

| 280S | 457 | 368 | 190 | 75 | 20 | 67.5 | 280 | 550 | 5 80 | 410 | 680 | 1 100 | ||

| 280M | 419 | 20 | 71 | 11 80 | ||||||||||

| 315S | 508 | 406 | 216 | 80 | 170 | 22 | 71 | 315 | 28 | 635 | 645 | 5 30 | 845 | 1330 |

| 315M | 457 | 1390 | ||||||||||||

| 315L | 508 | 1480 | ||||||||||||

| 3 55M | 610 | 560 | 254 | 95 | 170 | 25 | 86 | 355 | 730 | 730 | 655 | 1100 | 1750 | |

| 3 5 5 L | 630 | 1800 |

||||||||||||

| Frame Size | Mounting Dimensions | Overall Dimensions | ||||||||||||

| D | E | F | G a | M | N | P b | S D | T | Number of Holes on the Flange | AC | AD | HF | L | |

| Basic Dimension | Basic Dimension | Basic Dimension | Basic Dimension | Basic Dimension | Basic Dimension | Basic Dimension | ||||||||

| 80M | 19 | 40 | 6 | 15.5 | 165 | 130 | 200 | 12 | 3.5 | 4 | 175 | 145 | 185 | 3 7 0 |

| 90S | 24 | 50 | 8 | 20 | 195 | 155 | 195 | 400 | ||||||

| 90L | 430 | |||||||||||||

| 100L | 28 | 60 | 24 | 215 | 180 | 250 | 15 | 4.0 | 215 | 180 | 245 | 465 | ||

| 112M | 240 | 190 | 265 | 490 | ||||||||||

| 132S | 38 | 80 | 10 | 33 | 265 | 230 | 300 | 275 | 210 | 315 | 5 30 | |||

| 132M | 575 | |||||||||||||

| 160M | 42 | 110 | 12 | 37 | 300 | 250 | 350 | 19 | 5.0 | 330 | 255 | 385 | 6 60 | |

| 160L | 715 | |||||||||||||

| 180M | 48 | 14 | 42.5 | 380 | 280 | 430 | 810 | |||||||

| 180L | 850 | |||||||||||||

| 200L | 55 | 16 | 49 | 350 | 300 | 400 | 420 | 305 | 480 | 890 | ||||

| 225S | 60 | 140 | 18 | 53 | 400 | 350 | 450 | 8 | 470 | 335 | 535 | 930 | ||

| 225M | 970 | |||||||||||||

| 250M | 65 | 58 | 500 | 450 | 550 | 510 | 370 | 595 | 1060 | |||||

| 280S | 75 | 20 | 67.5 | 580 | 410 | 650 | 1100 | |||||||

| 280M | 1180 | |||||||||||||

| Frame Size | Mounting Dimensions | Overall Dimensions | ||||||||||||||||||

| A | B | C | D | E | F | G A | H | K D | M | N | P B | S D | T | Number of Holes on the Flange | AB | AC | AD | HD | L | |

| Basic Dimension | Basic Dimension | Basic Dimension | Basic Dimension | Basic Dimension | Basic Dimension | Basic Dimension | Basic Dimension | Basic Dimension | Basic Dimension | Basic Dimension | Basic Dimension | |||||||||

| 80M | 125 | 100 | 50 | 19 | 40 | 6 | 15 . 5 | 80 | 10 | 165 | 130 | 200 | 12 | 3.5 | 4 | 165 | 175 | 145 | 2 20 | 3 7 0 |

| 90S | 140 | 56 | 24 | 50 | 8 | 20 | 90 | 180 | 195 | 155 | 250 | 400 | ||||||||

| 90L | 125 | 430 | ||||||||||||||||||

| 100L | 160 | 140 | 63 | 28 | 60 | 24 | 100 | 12 | 215 | 180 | 250 | 15 | 4.0 | 205 | 215 | 180 | 270 | 465 | ||

| 112M | 190 | 70 | 112 | 230 | 240 | 190 | 300 | 4 9 0 | ||||||||||||

| 132S | 216 | 89 | 38 | 80 | 10 | 33 | 132 | 265 | 230 | 300 | 270 | 275 | 210 | 345 | 5 30 | |||||

| 132M | 178 | 57 5 | ||||||||||||||||||

| 160M | 254 | 210 | 108 | 42 | 110 | 12 | 37 | 160 | 15 | 300 | 250 | 350 | 19 | 5.0 | 330 | 330 | 255 | 420 | 6 60 | |

| 160L | 254 | 715 | ||||||||||||||||||

| 180M | 279 | 241 | 121 | 48 | 14 | 42 .5 | 180 | 355 | 380 | 280 | 45 5 | 810 | ||||||||

| 180L | 279 | 850 | ||||||||||||||||||

| 200L | 318 | 305 | 133 | 55 | 16 | 49 | 200 | 19 | 350 | 300 | 400 | 395 | 420 | 305 | 505 | 8 90 | ||||

| 225S | 356 | 286 | 149 | 60 | 140 | 18 | 53 | 225 | 400 | 350 | 450 | 8 | 435 | 470 | 335 | 560 | 930 | |||

| 225M | 311 | 970 | ||||||||||||||||||

| 250M | 406 | 349 | 168 | 6 5 | 58 | 250 | 24 | 500 | 450 | 550 | 490 | 510 | 370 | 61 5 | 1050 | |||||

| 280S | 457 | 368 | 190 | 75 | 20 | 67.5 | 280 | 550 | 580 | 410 | 680 | 110 0 | ||||||||

| 280M | 419 | 11 80 | ||||||||||||||||||

| 315S | 508 | 406 | 216 | 80 | 170 | 22 | 71 | 3 1 5 | 28 | 600 | 550 | 660 | 24 | 6.0 | 6 35 | 6 45 | 5 3 0 | 845 | 1330 | |

| 315M | 457 | 1390 | ||||||||||||||||||

| 3 15L | 508 | 1480 | ||||||||||||||||||

| 3 5 5 M | 610 | 560 | 254 | 95 | 25 | 86 | 355 | 28 | 740 | 680 | 800 | 24 | 6.0 | 8 | 7 3 0 | 710 | 655 | 1100 | 1750 | |

| 355L | 630 | 1800 |

||||||||||||||||||

| Frame Size | Mounting Dimensions | Overall Dimensions | ||||||||||||

| D | E | F | G a | M | N | P | S d | T | Number of Holes on the Flange | AC | AD | HF | L | |

| Basic Dimension | Basic Dimension | Basic Dimension | Basic Dimension | Basic Dimension | Basic Dimension | Basic Dimension | ||||||||

| 80 | 19 | 40 | 6 | 15.5 | 165 | 130 | 200 | 12 | 3.5 | 4 | 165 | 175 | 260 | 370 |

| 90S | 24 | 50 | 8 | 20 | 180 | 180 | 270 | 400 | ||||||

| 90L | 430 | |||||||||||||

| 100L | 28 | 60 | 24 | 215 | 180 | 250 | 15 | 4.0 | 205 | 195 | 300 | 465 | ||

| 112M | 230 | 205 | 320 | 490 | ||||||||||

| 132S | 38 | 80 | 10 | 33 | 265 | 230 | 300 | 270 | 265 | 380 | 530 | |||

| 132M | 575 | |||||||||||||

| 160M | 38 | 110 | 12 | 37 | 300 | 250 | 350 | 19 | 5.0 | 325 | 270 | 450 | 660 | |

| 160L | 715 | |||||||||||||

| 180M | 48 | 14 | 42.5 | 380 | 280 | 500 | 788 | |||||||

| 180L | 820 | |||||||||||||

| 200L | 55 | 16 | 49 | 350 | 300 | 400 | 420 | 305 | 550 | 960 | ||||

| 225S | 60 | 140 | 18 | 53 | 400 | 350 | 450 | 8 | 470 | 335 | 610 | 1020 | ||

| 225M | 1060 | |||||||||||||

| 250M | 65 | 58 | 500 | 450 | 550 | 510 | 370 | 650 | 1160 | |||||

| 280S | 75 | 20 | 67.5 | 580 | 410 | 720 | 1220 | |||||||

| 280M | 1300 | |||||||||||||

| 315S | 80 | 170 | 22 | 71 | 600 | 550 | 660 | 24 | 6.0 | 645 | 530 | 900 | 1530 | |

| 315M | 1520 | |||||||||||||

| 315L | 1610 | |||||||||||||

| 355M | 95 | 170 | 25 | 86 | 740 | 680 | 800 | 710 | 655 | 1100 | 1890 | |||

| 355L | 1940 |

|||||||||||||

Ordering Information

1. When placing an order, specify the motor’s type, output, number of poles, voltage, frequency, mounting arrangement and any other requirements.

2. Customized features include the double shaft extension, position of the terminal box, coding device and brake, and thermistor protection.

3. We also offer 2P frequency changeable motors upon request.

English

English Русский

Русский العربية

العربية